CO2 Total Flooding System

Fixed fire extinguishers on board are installed to fight large fires that require complete evacuation of the area engulfed by the fire.

CO2 total flooding system is predominantly installed on board cargo vessels to deal with large fires in Engine room as well as in Cargo holds.

Advantages of using CO2

Non-corrosive.

Non-poisonous.

Non-conductor of electricity.

Leaves no residues.

Capable of entering inaccessible areas.

How CO2 fights fire

CO2 extinguishes a fire by smothering or cutting off oxygen supply.

As CO2 is much heavier than air,it settles at the bottom,displaces air and forms a blanket-like cover over the fire.As a result,fire is starved of oxygen and is extinguished.

Main components (CO2 total flooding system)

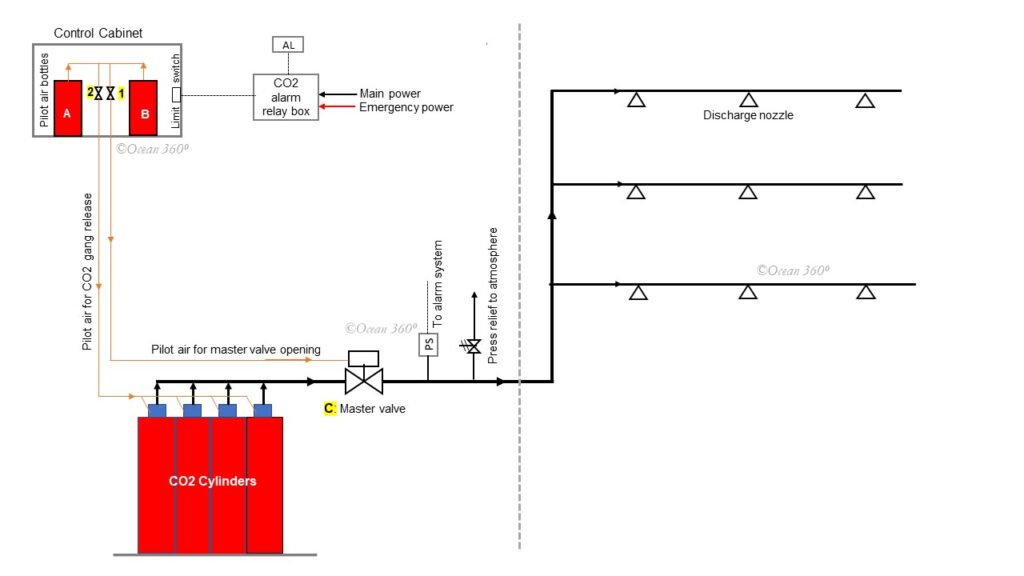

In reference to the Fig. 1 below.

Control Cabinet – Located at remote fire control station.Having pilot air bottles(A & B – two in each cabinet for redundancy),two lever operated ball valves(1 & 2)- one for CO2 gang release and the other for master valve actuation,limit switch that triggers fire alarm whenever the cabinet door is opened.

Fig. 1 CO2 total flooding system for machinery spaces

CO2 cylinders– Each cylinder contains 45 kg liquid CO2.Cylinder valve assembly fitted on top of each cylinder is actuated by pilot air.In addition, manual release handle is fitted for emergency operation.A safety disc is fitted with each cylinder valve assembly which will burst out in case of over-pressurization of the cylinder.

Pilot air tubing – Generally,small diameter copper tubes.Supply pressurized pilot air from pilot bottles to the CO2 cylinder valve assembly and the master valve actuator.

Flexible hoses– Connect CO2 cylinder valve assembly to the CO2 discharge piping system(manifold).Discharged CO2 from the cylinders passes to the manifold through these flexible hoses.Each flexible hose is fitted with a check valve (non-return valve) at the manifold-end.

Master Valve(C) – The main valve in the discharge piping system.Fitted with limit switches and triggers CO2 alarm whenever the valve opens.

Discharge nozzles -Installed strategically in the areas to be protected.

Pressure relief valve (at the manifold)– protects the CO2 manifold form abnormal pressure build-up.

Explosion proof audio-visual CO2 alarm -located in machinery spaces.

Pressure switch (at the manifold)– Triggers alarm whenever manifold pressure reaches pre-set value due to inadvertent CO2 leakage to the manifold.

In addition to above, Cargo Hold CO2 Flooding system includes followings:

Pneumatic change over valves.

Explosion proof air horns (located in the holds).

Standalone smoke detection unit with motor-driven suction fans.

CO2 Flooding System for Engine Room & Machinery Spaces

Before operating CO2 total flooding system,complete evacuation,shutting down and sealing off must be ensured.

CO2 fixed fire extinguishing system can be operated either remotely from the fire control station or locally from the CO2 room.But it is always preferable to operate remotely as long as situation permits.

Ref. to the fig.1 above,whenever the door of the control cabinet,situated at the remote fire control station,is opened,an audio-visual CO2 alarm is triggered into function.This CO2 alarm is powered by the vessel’s main power source and backed up by the emergency source.

Inside the control cabinet there are two small pilot air bottles(A & B).Two bottles are installed for redundancy.

First of all,shut-off valve on top of any of the pilot air bottles(A or B) to be opened and the pressure indicated at the gauge to be checked carefully. If the gauge reading is within the range,the second bottle is not required to be opened.

Then open valve (1) & valve (2) in sequence,by operating respective lever.Operating valve 1 will lead pilot air to the master valve actuator and open the master valve (C).In the same way,pilot air through valve 2 will actuate cylinder valves fitted atop the CO2 cylinders and release CO2 from the cylinders simultaneously.Discharged CO2 will be released in gaseous form through the nozzles located strategically in the protected areas and smoother the fire.

Emergency Release

In case of failure or breakdown of the system for remote operation,CO2 still can be released locally from the CO2 room.

This will require opening the master valve(C) manually,followed by the gang release of CO2 by operating emergency hand levers fitted on CO2 cylinders.

Only required number of CO2 cylinders as per the chart to be released.

-the end