Cavitation & NPSH are widely talked about terms associated with centrifugal pumps

Cavitation & NPSH these two terms are closely interrelated.

NPSH is the cause & Cavitation is the effect.

NPSH

NPSH stands for Net Positive Suction Head.

To put it simply – it is the resultant pressure energy or head available at the pump’s suction that pushes the fluid to flow or to be drawn in towards impeller nozzle,overcoming vapor pressure.

A fluid in its path from tank to pump suction encounters a number of pressure heads which either pushes the fluid towards the impeller nozzle or opposes the flow.The resultant positive head or pressure energy available at the impeller nozzle is termed as Net Positive Suction Head(NPSH).

NPSH is calculated by subtracting negative pressure energies,mainly the vapor pressure of the fluid to be pumped,form total pressure head available at the pump suction.

NPSH = Total Pressure energy(head) at pump suction – Vapor pressure (of fluid to be pumped)

It is termed as Net Positive Suction head,as mathematically,it is the summation of a number of pressure heads (pressure energies) either pushing or countering the flow to suction side of the pump.

NPSH is a critical criterion for designing, installing & operating centrifugal pumps.It’s imperative that NPSH is positive with certain margin. Inadequate NPSH will lead to Cavitation,fall in performance and in the worst case total loss of pumpability.

Cavitation

Cavitation,as its name implies,is the erosion,pitting or formation of cavities on impeller,casing or other parts of the pump or in the pipeline,due to rapid formation & busting of vapor bubbles in the flow of liquid.

How cavitation takes place

It’s a universal property of any fluid- the lower is the surrounding pressure,the lower is the required temperature for evaporation.

In course of its flow through the pump liquid passes two completely different pressure zones:

- Low pressure zone

- High pressure zone

At the suction side of the pump vacuum or low-pressure zone exists.Temperature of the liquid flowing through pump might be close to above evaporation temperature(for the existing pressure).As a result,part of the fluid while entering impeller eyelet may got vaporized & forms bubbles. This vaporization & bubble formation tendency will be significant if the temp of the liquid is more than the specified one for any reason.

The vapor bubbles formed,in this way,may collapse in course of the flow upon reaching high pressure zones,for example-at the tip of impeller vanes or anywhere in the delivery side.This rapid formation and bursting of bubbles generate significant shock waves.

The hammering effect resulted from the shock waves may cause significant cavities,pitting or erosion on impeller,casing, pipelines,valves etc.

Cavitation will be apparent by excessive vibration,abnormal noise-like sand going through the pump,pressure fluctuation,overheating of pump casing etc.

How to counter cavitation

NPSH has two components:

I. NPSHa – Net Positive Suction Head Available.It the NPSH actually available at the suction of a pump in a given condition.

II. NPSHr – Net Positive Suction Head Required.It is the suction pressure necessary to ensure proper pump operation.

NPSHa for given pump is affected by a number of factors:

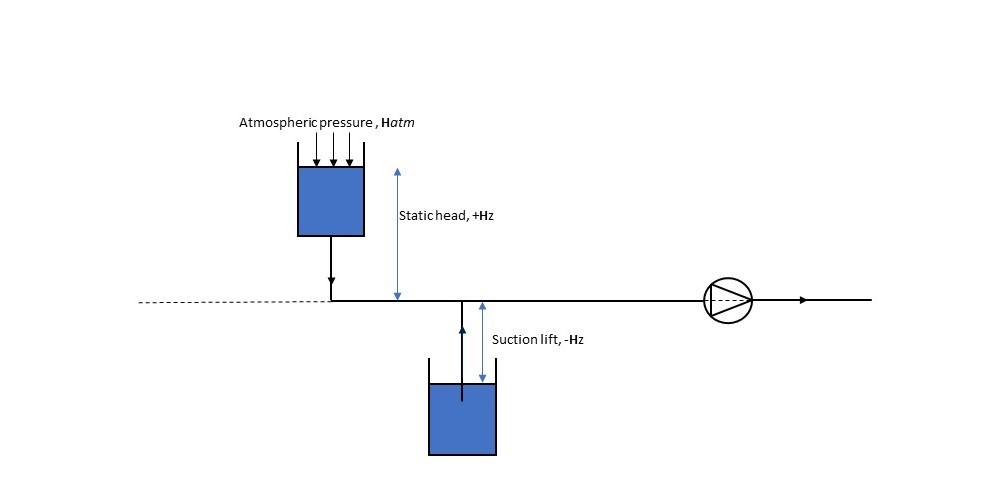

Hatm : Atmospheric pressure acting on the liquid surface to be pumped (+ve head)

Hz : Static head or suction lift. If the level liquid to be pumped is located above the center line of the pump Hz will (+ve) and termed as Static head. If the liquid level is below the center line Hz will be (-ve) and termed as Suction Lift

Hf : Friction loss inside the suction pipe

Hvap: Vapor pressure of the liquid at the impeller nozzle (varies with temperature of the liquid)

NPSHa = Hatm ± Hz -Hf – Hvap

Fig.1 NPSHa at pump suction

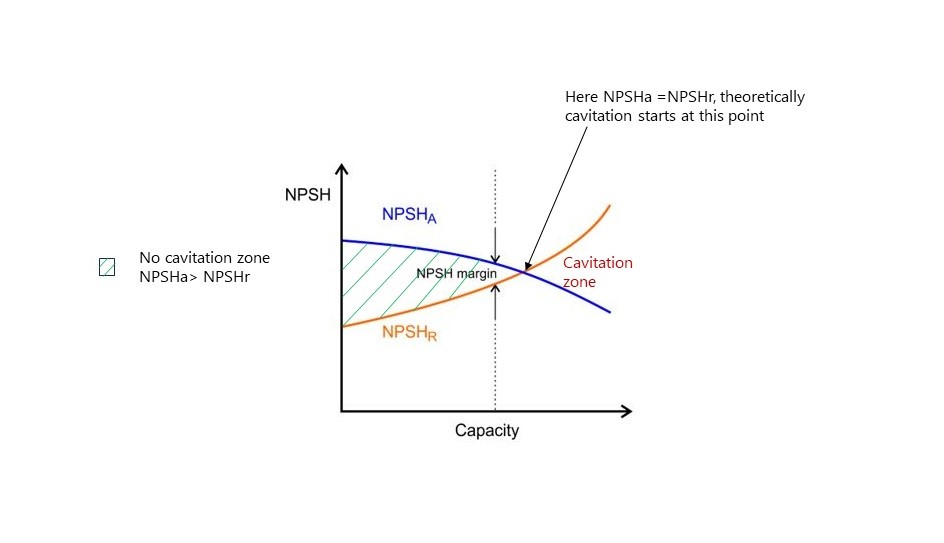

in order to rule out the possibility of cavitation during design & installation stage all the factors that may be encountered are taken into consideration and adequate margin is included as reserve: NPSHa ≥ NPSHr + margin

Fig.2 No-cavitation zone vs Cavitation zone

-the end.